The digital transformation applied to the industrial context is called Industry 4.0, and consists of the application of cyber-physical systems that connect processes, people, machines and products to each other.

Industry 4.0 is the term used in Europe to name the fourth industrial revolution, which consists of the fusion of traditional production methods with the latest technological developments in the fields of information and communication. This concept represents an evolution of production systems that translates into benefits for organizations, associated with cost reduction, energy savings, increased safety and quality, improved process efficiency, among others.

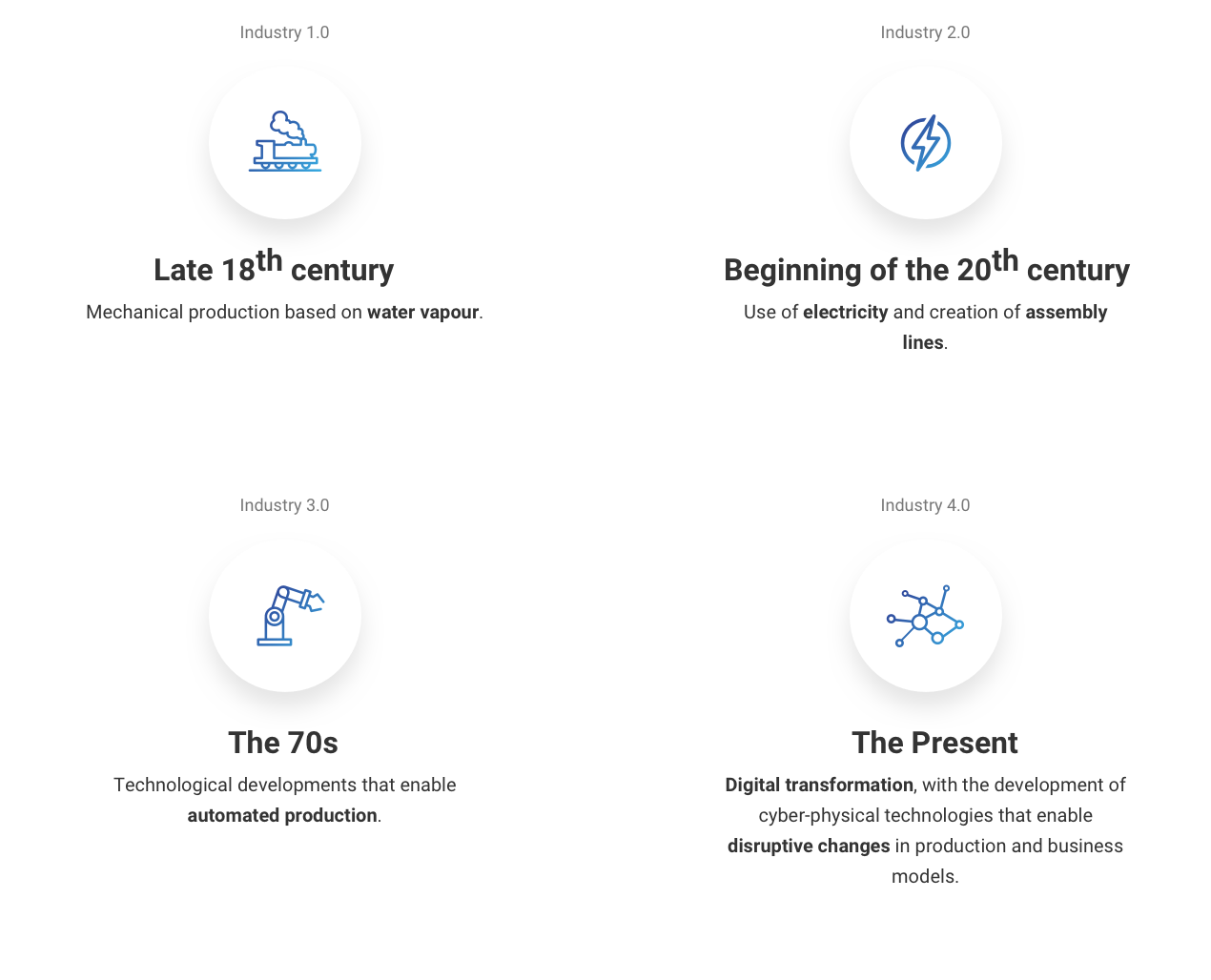

Throughout history, the industry has undergone revolutions normally associated with the emergence of new technologies or new forms of production, from mechanization arising from the creation of the steam engine, through large-scale production resulting from the application of the concept of assembly lines to the automation and robotization of processes. Today, at the heart of this most recent revolution, is digital connectivity, which also comes from the mass use of the internet. Although each company is distinct, they all face a common challenge - the need to be connected and have access, in real-time, to information about their processes, partners, products and clients.

This is precisely the principle of Industry 4.0, that the combination of physical products and operations with technology (cyber-physical systems), will enable the creation of a more holistic and more connected ecosystem, for all organizations. Through this connection between the physical and the virtual world, a horizon of new opportunities opens up and changes not only the way companies operate, but also allows for the creation of new business models and new production methods, ensuring a more effective and integrated connection to consumers, who are also increasingly connected and more demanding, accelerating the innovation cycles and their arrival on the market, and allowing for an increase in productivity and a reduction of risk.

The new industrial environment is characterized by a commitment to collaborative innovation, connected and flexible means of production, integrated logistics chains and digital distribution and client service channels.

In short, a smart and connected industry model.

The THRUST model - Technological and Holistic Readiness on Use of Standards & Certification Tool, was created within the scope of the Portugal Industry 4.0 Platform Project, as a way to raise awareness, diagnose and enable the Portuguese businesses, for the use of standards and certification of management systems in accordance with sectoral and transversal standards, as a necessary condition for integration in global value chains.

Given the importance of Industry 4.0, the Ministry of Economy, with the purpose of promoting conditions for the development of national industry and services in the digital age, decided to launch the Portugal i4.0 initiative in order to identify the needs of the Portuguese companies and guide measures (public and private) in order to achieve three central objectives:

Within the scope of the activities for which it is a promoter, COTEC promotes the Portugal i4.0 Platform Project, which intends to train and qualify national Small and Medium Enterprises (SMEs) to face the challenges of the Industry 4.0 paradigm, with the objective of filling the fill gaps and deficiencies in the incorporation of concepts and technologies characteristic of the fourth industrial revolution, contributing to reinforce management and innovation skills, and thus the respective competitiveness of companies.

In this sense, the activity of the Portugal i4.0 Platform emerges in the development of a Maturity Assessment Model for the adoption of standards and certification of management systems, which aims to serve as a self-diagnosis path for SMEs, enabling the understanding of their level of development of process management and preparation for the new Industry 4.0 paradigm.

Considering the importance of companies adapting to the new operating requirements in the market, in a reality characterized by industry 4.0, the adoption of standards and certification of management systems implies an increase in efficiency and predictability in production systems, translating into an increase in consumer confidence.